Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method

Abstract

:1. Introduction

2. Methodology

2.1. Schedule, Methods, and Scope of Research

2.2. General Characteristics of the WWTP

3. Results

- Screens building (2 points)—odor concentration 2 ou/m3, maximum range 180 m. The odor of screenings was perceptible outside the area of the WWTP.

- Piles of dewatered sludge (6 points)—odor concentration 2–3 ou/m3, maximum range 580 m. The odor of excess sludge was perceptible outside the WWTP.

- Small heap of screenings (2 points)—odor concentration 2 ou/m3, maximum range 166 m. The odor of screenings was perceptible outside the WWTP.

4. Discussion

5. Summary and Conclusions

- Air inflowing over the area of the WWTP was clean in terms of odor. The level of the so-called background for odor intensity and concentration was zero. This means no occurrence (no identification) of sources of emission of odorants/odors, the impact of which would overlap with the impact of the analyzed object.

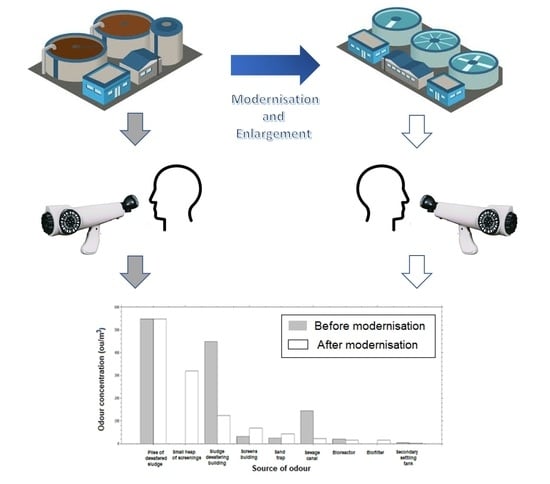

- In the area of the wastewater treatment installation—before and after modernization—odor intensity changed in a complete range (from i = 0 to i = 5), and odor concentration from 0 to 549 ou/m3.

- Sources emitting odor with a maximum concentration value of 549 ou/m3 were piles of dewatered sludge in the waste storage yard.

- Other odorant emitters included, in order of the degree of odor nuisance: A small heap of screenings deposited in the waste storage yard after modernization (maximum odor concentration value 319 ou/m3), and a container for dewatered sludge located at a distance of 10 m south of the building of mechanical sludge thickening and dewatering. During its filling with sludge from the sludge dewatering building, the maximum odor concentration value before modernization was 450 ou/m3, while after modernization, 123 ou/m3.

- The source of odor of raw sewage and screenings was the screens building. The maximum odor concentration value was 68 ou/m3 (that value was achieved after modernization). Insufficient air-tightening of the object (crevice under the gate of the screens hall) contributed to spreading of odorous substances.

- Odor impact outside the WWTP was determined in three out of the twelve performed series of olfactometric research concerning air quality. In these cases, odor of screenings from the screens building and a small heap of screenings was observed, as well as odor of dewatered sludge from the piles deposited in the sludge storage yard. The maximum range of impact of the WWTP was 580 m, and the maximum odor concentration value recorded outside the plant reached 3 ou/m3.

- Modernization and enlargement of the technological sequence of biological reactors and secondary settling tanks had no effect on the emission of odorants from the objects.

- During all the series of field research, the plant’s gas station in the north-eastern part of the WWTP was determined not to constitute a source of odor impact.

Author Contributions

Funding

Conflicts of Interest

References

- Badach, J.; Kolasińska, P.; Paciorek, M.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Dymnicka, M.; Namieśnik, J. A case study of odour nuisance evaluation in the context of integrated urban planning. J. Environ. Manag. 2018, 213, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Runhaar, H.; Driessen, P.P.J.; Soer, L. Sustainable urban development and the challenge of policy integration: An assessment of planning tools for integrating spatial and environmental planning in The Netherlands. Environ. Plan. 2019, 36, 417–431. [Google Scholar] [CrossRef]

- Wu, C.; Brancher, M.; Yang, F.; Liu, J.; Qu, C.; Schauberger, G.; Piringer, M. A Comparative Analysis of Methods for Determining Odour-Related Separation Distances around a Dairy Farm in Beijing, China. Atmosphere 2019, 10, 231. [Google Scholar] [CrossRef]

- Adams, G.; Witherspoon, J. Identifying and controlling odor in the municipal wastewater environment phase 1: Literature search and review. IWA Publ. 2003, 3. [Google Scholar] [CrossRef]

- Brancher, M.; Griffiths, K.D.; Franco, D.; de Melo Lisboa, H. A review of odour impact criteria in selected countries around the world. Chemosphere 2017, 168, 1531–1570. [Google Scholar] [CrossRef] [PubMed]

- Brambilla, M.; Navarotto, P. Sensorial analysis of pig barns odour emissions. Chem. Eng. Trans. 2010, 23, 243–248. [Google Scholar] [CrossRef]

- Guffanti, P.; Pifferi, V.; Falciola, L.; Ferrante, V. Analyses of odours from concentrated animal feeding operations: A review. Atmos. Environ. 2018, 175, 100–108. [Google Scholar] [CrossRef]

- Hansen, M.J.; Jonassen, K.E.N.; Lokke, M.M.; Adamsen, A.P.S.; Feilberg, A. Multivariate prediction of odor from pig production based on in-situ measurement of odorants. Atmos. Environ. 2016, 135, 50–58. [Google Scholar] [CrossRef]

- Harrison, E.Z.; Oakes, S.R. Investigation of alleged health incidents associated with land application of sewage sludges. New Solut. 2002, 12, 387–408. [Google Scholar] [CrossRef] [PubMed]

- Hayes, J.E.; Stevenson, R.J.; Stuetz, R.M. The impact of malodour on communities: A review of assessment techniques. Sci. Total Environ. 2014, 500–501, 395–407. [Google Scholar] [CrossRef] [PubMed]

- Gostelow, P.; Parsons, S.A.; Stuetz, R. Odour measurements for the sewage treatment works. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef]

- Pan, L.; Yang, S.X.; de Bruyn, J. Factor analysis of downwind odours from livestock farms. Biosyst. Eng. 2007, 96, 387–397. [Google Scholar] [CrossRef]

- Rappert, S.; Muller, R. Odor compounds in waste gas emissions from agricultural operations and food industries. Waste Manag. 2005, 25, 887–907. [Google Scholar] [CrossRef] [PubMed]

- Shusterman, D. The health significance of environmental odour pollution: Revisited. J. Environ. Med. 1999, 1, 249–258. [Google Scholar] [CrossRef]

- Toledo, M.; Diles, J.A.; Gutierrez, M.C.; Martin, M.A. Monitoring of the composting process of different agroindustrial waste: Influence of the operational variables on the odorous impact. Waste Manag. 2018, 76, 266–274. [Google Scholar] [CrossRef] [PubMed]

- Van Harreveld, A.P. Odour management tools—Filling in the gaps. Water Sci. Technol. 2004, 50, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Wi, J.; Lee, S.; Kim, E.; Lee, M.; Koziel, J.; Ahn, H. Evaluation of Semi-Continuous Pit Manure Recharge System Performance on Mitigation of Ammonia and Hydrogen Sulfide Emissions from a Swine Finishing Barn. Atmosphere 2019, 10, 170. [Google Scholar] [CrossRef]

- Zhu, W.; Koziel, J.; Maurer, D.L. Mitigation of Livestock Odors Using Black Light and a New Titanium Dioxide-Based Catalyst: Proof-of-Concept. Atmosphere 2017, 8, 103. [Google Scholar] [CrossRef]

- Agus, E.; Zhang, L.; Sedlak, D.L. A framework for identifying characteristic odor compounds in municipal wastewater effluent. Water Res. 2002, 46, 5970–5980. [Google Scholar] [CrossRef] [PubMed]

- Byliński, H.; Gębicki, J.; Namieśnik, J. Evaluation of Health Hazard Due to Emission of Volatile Organic Compounds from Various Processing Units of wastewater treatment plant. Int. J. Environ. Res. Public Health 2019, 16, 1712. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, D.; Colon, J.; Sanchez, A.; Gabriel, D. A systematic study on the VOCs characterization full-scale sewage sludge composting plant. J. Hazard. Mater. 2019, 373, 733–740. [Google Scholar] [CrossRef] [PubMed]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Bruszkiewski, H.; Skorupski, W. Air pollution caused by a concentrated liquid waste treatment plant. Chem. Inżynieria Ekol. 1999, 10, 979–987. [Google Scholar]

- Lewkowska, P.; Cieślik, B.; Dymerski, T.; Konieczka, P.; Namieśnik, J. Characteristics of odors emitted from municipal wastewater treatment plant and methods for their identification and deodorization techniques. Environ. Res. 2016, 151, 573–586. [Google Scholar] [CrossRef] [PubMed]

- Aatamila, M.; Verkasalo, P.K.; Korhonen, M.J.; Suominen, A.L.; Hirvonen, M.-R.; Viluksela, M.K.; Nevalainen, A. Odour annoyance and physical symptoms among residents living near waste treatment centres. Environ. Res. 2011, 111, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.J.; Yang, N.; Cen, D.Y.; Shao, L.M.; He, P.J. Odor compounds from different sources of landfill: Characterization and source identification. Waste Manag. 2012, 32, 1401–1410. [Google Scholar] [CrossRef] [PubMed]

- González, I.; Robledo-Mahón, T.; Silva-Castro, G.A.; Rodríguez-Calvo, A.; Gutiérrez, M.C.; Martín, M.A.; Chica, A.F.; Calvo, C. Evolution of the composting process with semi-permeable film technology at industrial scale. J. Clean. Prod. 2016, 115, 245–254. [Google Scholar] [CrossRef]

- Gutiérrez, M.C.; Martin, M.A.; Chica, A.F. Usual variables and odour concentration to evaluate composting process and odour impact. Environ. Technol. 2014, 35, 709–718. [Google Scholar] [CrossRef] [PubMed]

- Kulig, A.; Szyłak-Szydłowski, M. Assessment of Range of Olfactory Impact of Plant to Mechanical-Biological Treatment of Municipal Waste. Chem. Eng. Trans. 2016, 54, 247–252. [Google Scholar] [CrossRef]

- Sironi, S.; Capelli, L.; Céntola, P.; Del Rosso, R.; Pierucci, S. Odor impact assessment by means of dynamic olfactometry, dispersion modelling and social participation. Atmos. Environ. 2010, 44, 354–360. [Google Scholar] [CrossRef]

- Szyłak-Szydłowski, M. Odour Samples Degradation During Detention in Tedlar® Bags. Water Air Soil Pollut. 2015, 226, 38–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Szyłak-Szydłowski, M. Validation of odor concentration from mechanical-biological treatment piles using static chamber and wind tunnel with different wind speed values. J. Air Waste Manag. Assoc. 2017, 67, 1046–1054. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barczak, R.; Kulig, A.; Szyłak-Szydłowski, M. Olfactometric methods application for odour nuisance assessment of wastewater treatment facilities in Poland. Chem. Eng. Trans. 2012, 30, 187–192. [Google Scholar] [CrossRef]

- Blanes-Vidal, V.; Hansen, M.N.; Adamsen, A.P.S.; Feilberg, A.; Petersen, S.O.; Jensen, B.B. Characterization of odor released during handling of swine slurry: Part, I. Relationship between odorants and perceived odor concentrations. Atmos. Environ. 2009, 43, 2997–3005. [Google Scholar] [CrossRef]

- Hobbs, P. Odour analysis by gas chromatography. In Odours in Wastewater Treatment: Measurement, Modelling and Control; Stuetz, R.M., Frechen, F.-B., Eds.; IWA Publishing: London, UK, 2001. [Google Scholar]

- Tsai, C.J.; Chen, M.L.; Ye, A.D.; Chou, M.S.; Shen, S.H.; Mao, I.F. The relationship of odor concentration and the critical components emitted from food waste composting plants. Atmos. Environ. 2008, 42, 8246–8251. [Google Scholar] [CrossRef]

- Dincer, F.; Muezzinoglu, A. Odor determination at wastewater collection systems: Olfactometry versus H2S analyses. Clean 2007, 35, 565–570. [Google Scholar] [CrossRef]

- Gostelow, P.; Parsons, S.A. Sewage treatment works odor measurement. Water Sci. Technol. 2000, 41, 33–40. [Google Scholar] [CrossRef]

- Wang, B.; Sivret, E.C.; Parcsi, G.; Wang, X.; Stuetz, R.M. Characterising volatile organic compounds from sewer emissions by thermal desorption coupled with gaschromatography-mass spectrometry. Chem. Eng. Trans. 2012, 30, 73–78. [Google Scholar] [CrossRef]

- Nicell, J.A. Assessment and regulation of odour impacts. Atmos. Environ. 2009, 43, 196–206. [Google Scholar] [CrossRef]

- Brattoli, M.; de Gennaro, G.; de Pinto, V.; Loiotile, A.D.; Lovascio, S.; Penza, M. Odour Detection Methods: Olfactometry and Chemical Sensors. Sensors 2011, 11, 5290–5322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Capelli, L.; Sironi, S.; Del Rosso, R. Electronic noses for environmental monitoring applications. Sensors 2014, 14, 19979–20007. [Google Scholar] [CrossRef] [PubMed]

- McGinley, C. Standardized odor measurement practices for air quality testing. In Proceedings of the Air and Waste Management Association Symposium on Air Quality Measurement, Methods and Technology, San Francisco, CA, USA, 13–15 November 2002. [Google Scholar]

- Frechen, F.B. Regulations and policies. In Odours in Wastewater Treatment: Measurement, Modelling and Control; Stuetz, R.M., Frechen, F.-B., Eds.; IWA Publishing: London, UK, 2001. [Google Scholar]

- Cheng, X.H.; Peterkin, E.; Narangajavana, K. Wastewater analysis for volatile organic sulfides using purge-and-trap with gas chromatography/mass spectrometry. Water Environ. Res. 2007, 79, 442–446. [Google Scholar] [CrossRef] [PubMed]

- Munoz, R.; Sivert, E.C.; Parcsi, G.; Lebrero, R.; Wang, X.; Suffet, I.H.; Stuetz, R.M. Monitoring techniques for odour abatement assessment. Water Res. 2010, 44, 5129–5149. [Google Scholar] [CrossRef] [PubMed]

- Szyłak-Szydłowski, M. Comparison of two types of field olfactometers for assessing odours in laboratory and field tests. Chem. Eng. Trans. 2014, 40, 67–72. [Google Scholar] [CrossRef]

- Turkmen, M.; Dentel, S.K.; Chiu, P.C.; Hepner, S. Analysis of sulfur and nitrogen odorants using solid-phase microextraction and GC-MS. Water Sci. Technol. 2004, 50, 115–120. [Google Scholar] [CrossRef] [PubMed]

- VDI 3940 Part 2: Measurement of Odour Impact by Field Inspection—Measurement of the Impact Frequency of Recognizable Odours Plume Measurement. Available online: https://www.nhbs.com/vdi-3940-part-2-measurement-of-odour-impact-by-field-inspection-measurement-of-the-impact-frequency-of-recognizable-odours-plume-measurement-book (accessed on 12 November 2019).

- Belgiorno, V.; Naddeo, V.; Zarra, T. Odour Impact Assessment Handbook, 1st ed.; John Wiley & Sons Ltd.: London, UK, 2013. [Google Scholar]

- Dentoni, L.; Capelli, L.; Sironi, S.; Guillot, J.-M.; Rossi, A.N. Comparison of different approaches for odour impact assessment: Dispersion modelling (CALPUFF) vs field inspection (CEN/TC 264). Water Sci. Technol. 2013, 68, 1731–1737. [Google Scholar] [CrossRef] [PubMed]

- Eusebio, L.; Dentoni, L.; Capelli, L.; Sironi, S.; Rossi, A.N.; Bonati, S. Odour impact assessment in the field: The plume method. Environ. Eng. Manag. J. 2013, 12, 193–196. [Google Scholar]

- Karageorgos, P.; Latos, M.; Kotsifaki, C.; Lazaridis, M.; Kalogerakis, N. Treatment of unpleasant odors in municipal wastewater treatment plants. Water Sci. Technol. 2010, 61, 2635–2644. [Google Scholar] [CrossRef] [PubMed]

- Doshi, V.A.; Vuthaluru, H.; Bastow, T. Investigations into the control of odour and viscosity of biomass oil derived from pyrolysis of sewage sludge. Fuel Process. Technol. 2005, 86, 885–897. [Google Scholar] [CrossRef]

- Fisher, R.M.; Le-Minh, N.; Sivret, E.C.; Alvarez-Gaitan, J.P.; Moore, S.J.; Stuetz, R.M. Distribution and sensorial relevance of volatile organic compounds emitted throughout wastewater biosolids processing. Sci. Total Environ. 2017, 599–600, 663–670. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Hallis, S.A.; Vitko, T.; Suffet, I.H. Identification, quantification and treatment of fecal odors released into the air at two wastewater treatment plants. J. Environ. Manag. 2016, 180, 257–263. [Google Scholar] [CrossRef] [PubMed]

- Fisher, R.; Barczak, R.; Suffet, I.H.; Hayes, E.J.; Stuetz, R.M. Framework for the use of odour wheels to manage odours throughout wastewater biosolids processing. Sci. Total Environ. 2018, 634, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Rincon, C.A.; De Guardia, A.; Couvert, A.; Soutrel, I.; Guezel, S.; Le Serrec, C. Odor generation patterns during different operational composting stages of anaerobically digested sewage sludge. Waste Manag. 2019, 95, 661–673. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Sattayatewa, C.; Venkatesan, D.; Noll, K.E.; Pagilla, K.R.; Moschandreas, D.J. Modeling indoor odoreodorant concentrations and the relative humidity effect on odor perception at a water reclamation plant. Atmos. Environ. 2011, 45, 7235–7239. [Google Scholar] [CrossRef]

- Witherspoon, J.R.; Barnes, J.L. Comparison of methods used to measure odour at wastewater treatment plant fencelines. In Proceedings of the Environmental Odour Management International Conference, Cologne, Germany, 17–19 November 2004; pp. 363–375. [Google Scholar]

- Cesca, J.; Flanagan, A.; Cunnington, M. Case Study: Odour Risk Management at the WTP, One of Australia’s Largest Most Unique WWTPs. Semanticscholar 2007. Available online: https://www.semanticscholar.org/paper/Case-Study-%3A-Odour-Risk-Management-at-the-WTP-%2C-One-Cesca/fe6236cff0b15c65d5ce3aaa793c6b4ada6783a2 (accessed on 12 November 2019). [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Centola, P. Predicting odour emissions from wastewater treatment plants by means of odour emission factors. Water Res. 2009, 43, 1977–1985. [Google Scholar] [CrossRef] [PubMed]

- Littarru, P. Environmental odours assessment from waste treatment plants: Dynamic olfactometry in combination with sensorial analysers electronic noses. Waste Manag. 2007, 22, 302–309. [Google Scholar] [CrossRef] [PubMed]

- Stellacci, P.; Liberti, L.; Notarnicola, M.; Haas, C.N. Hygienic sustainability of site location of wastewater treatment plants: A case study. I. Estimating odour emission impact. Desalination 2010, 253, 51–56. [Google Scholar] [CrossRef]

| Series No. | Date of Research | Number of Receptors (points) | Total | Wind Speed (m/s) | Temperature (°C) | Humidity (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Within the Treatment Plant | Outside the Treatment Plant | Min | Max | Min | Max | Min | Max | |||

| I | 28.04.2015 | 24 | 12 | 36 | 0.8 | 3.2 | 21.6 | 24.4 | 40.0 | 63.2 |

| II | 05.05.2015 | 24 | 12 | 36 | 0.4 | 3.8 | 25.1 | 26.4 | 40.3 | 43.7 |

| III | 11.05.2015 | 24 | 12 | 36 | 0.9 | 2.3 | 11.0 | 12.9 | 58.4 | 71.2 |

| IV | 14.05.2015 | 24 | 12 | 36 | 1.0 | 1.9 | 12.2 | 14.6 | 48.0 | 78.4 |

| V | 19.05.2015 | 12 | 24 | 36 | 1.0 | 4.0 | 25.0 | 26.5 | 33.0 | 38.3 |

| VI | 20.05.2015 | 12 | 24 | 36 | 1.1 | 1.8 | 23.5 | 25.8 | 55.6 | 59.2 |

| VII | 22.05.2015 | 12 | 24 | 36 | 1.2 | 2.7 | 19.2 | 22.8 | 32.2 | 1.6 |

| VIII | 27.05.2015 | 6 | 30 | 36 | 2.4 | 3.8 | 13.5 | 15.0 | 56.5 | 66.1 |

| IX | 29.05.2015 | 12 | 24 | 36 | 0.9 | 1.9 | 19.5 | 21.6 | 38.0 | 50.2 |

| X | 03.06.2015 | 12 | 24 | 36 | 1.7 | 3.8 | 28.8 | 30.5 | 32.1 | 34.7 |

| Total: | - | 162 | 198 | 360 | - | - | - | - | - | - |

| Series No. | Date of Research | Number of Receptors (points) | Total | Wind Speed (m/s) | Temperature (%) | Humidity (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Within the Treatment Plant | Outside the Treatment Plant | Min | Max | Min | Max | Min | Max | |||

| I | 20.05.2016 | 36 | 12 | 48 | 0.9 | 2.5 | 19.3 | 30.8 | 21.2 | 34.2 |

| II | 16.06.2016 | 24 | 12 | 36 | 0.4 | 4.7 | 19.8 | 24.7 | 52.0 | 68.3 |

| III | 13.07.2016 | 24 | 12 | 36 | 0.3 | 1.4 | 24.1 | 29.5 | 4.7 | 67.2 |

| IV | 02.08.2016 | 24 | 12 | 36 | 0.4 | 1.9 | 18.0 | 26.4 | 49.8 | 76.7 |

| V | 18.08.2016 | 24 | 12 | 36 | 0.5 | 1.9 | 18.9 | 23.1 | 44.7 | 58.9 |

| VI | 08.09.2016 | 24 | 12 | 36 | 0.5 | 1.5 | 26.9 | 33.0 | 38.5 | 53.0 |

| VII | 19.10.2016 | 24 | 12 | 36 | 0.3 | 1.5 | 11.9 | 14.3 | 62.4 | 73.6 |

| VIII | 23.11.2016 | 24 | 12 | 36 | 0.4 | 1.7 | 7.8 | 10.4 | 64.2 | 74.3 |

| IX | 25.01.2017 | 24 | 12 | 36 | 0.3 | 1.9 | 1.9 | 4.5 | 76.3 | 87.0 |

| X | 24.02.2017 | 24 | 12 | 36 | 0.5 | 5.0 | 3.0 | 4.4 | 86.9 | 98.1 |

| XI | 29.03.2017 | 24 | 12 | 36 | 0.4 | 5.3 | 10.2 | 13.6 | 74.5 | 85.0 |

| XII | 26.04.2017 | 24 | 12 | 36 | 0.4 | 1.4 | 7.9 | 9.8 | 72.3 | 85.0 |

| Total: | - | 300 | 144 | 444 | - | - | - | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulig, A.; Szyłak-Szydłowski, M. Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method. Water 2019, 11, 2367. https://doi.org/10.3390/w11112367

Kulig A, Szyłak-Szydłowski M. Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method. Water. 2019; 11(11):2367. https://doi.org/10.3390/w11112367

Chicago/Turabian StyleKulig, Andrzej, and Mirosław Szyłak-Szydłowski. 2019. "Assessment of the Effects of Wastewater Treatment Plant Modernization by Means of the Field Olfactometry Method" Water 11, no. 11: 2367. https://doi.org/10.3390/w11112367